Product Category

Transportation of SF double-layer storage tank

Date: May 14, 2020

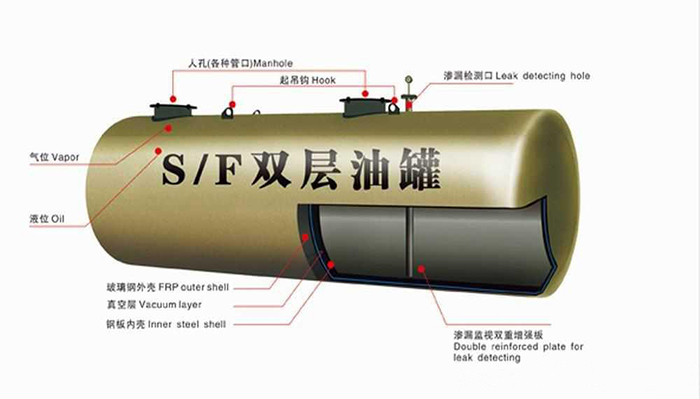

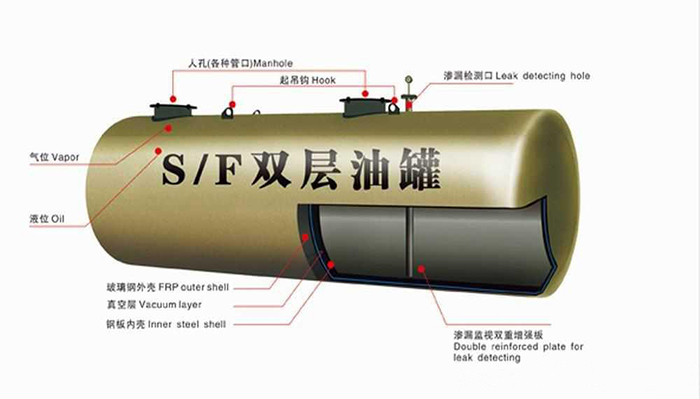

The double-layer storage tank mainly stores chemical solvents and petroleum products, and can be widely used in enterprises and units such as chemical industry, printing and dyeing, ink, gas station and so on. This product fills the gap in the domestic market. Compared with the single-layer iron storage tank widely used in China, it has a great improvement in both quality and service life, and has obvious features and advantages in terms of safety, economy and environmental protection.

The storage tank is equipped with a leak detector on the basis of the single-layer steel storage tank processed in accordance with the specifications, and at the same time, the surface of the single-layer storage tank is coated with a reinforced glass fiber layer (FRP) to form waterproof corrosion and The underground storage tanks with electrolytic corrosion protection layer are collectively called steel reinforced glass fiber storage tanks, hereinafter referred to as SF double-layer storage tanks.

When transporting the storage tank, the transportation vehicle must be installed with a support stand or sleepers to prevent overturning, and a 10 mm thick shock-absorbing rubber and plastic film are laid on the stand to prevent the outer layer of the storage tank from being damaged by impact. The position of sleepers should avoid welding seams and detection tubes. After the storage tank is hung on the transport truck and placed stably, it is necessary to confirm again whether the storage tank detection pressure gauge is -0.035Mpa. The storage tank should be fixed with cotton and hemp rope straps. The place where the straps contact the storage tank must be lined with rubber to prevent the FRP layer on the surface of the storage tank from being pinched. It is strictly forbidden to use metal ropes to fix the storage tank. After the storage tank is fixed, it must be covered with rainproof cloth or oil cloth. When the transport vehicle transports two storage tanks at the same time, the safe distance between the storage tank and the storage tank must be 350-400mm, and it must be separated by a rubber pad in the middle. The storage tank must be close to the end of the guardrail to ensure a safe distance ≥200mm. When the storage tank is transported by a flatbed truck, the bottom of the storage tank must be level.

When the transport vehicle transports two storage tanks at the same time, the safe distance between the storage tank and the storage tank must be 350-400mm, and it must be separated by a rubber pad in the middle. The storage tank must be close to the end of the guardrail to ensure a safe distance ≥200mm. When the storage tank is transported by a flatbed truck, the bottom of the storage tank must be level.

Note that the storage tank must be steadily transported to avoid rapid advance, emergency stop or driving on bumpy roads.

The storage tank is equipped with a leak detector on the basis of the single-layer steel storage tank processed in accordance with the specifications, and at the same time, the surface of the single-layer storage tank is coated with a reinforced glass fiber layer (FRP) to form waterproof corrosion and The underground storage tanks with electrolytic corrosion protection layer are collectively called steel reinforced glass fiber storage tanks, hereinafter referred to as SF double-layer storage tanks.

When transporting the storage tank, the transportation vehicle must be installed with a support stand or sleepers to prevent overturning, and a 10 mm thick shock-absorbing rubber and plastic film are laid on the stand to prevent the outer layer of the storage tank from being damaged by impact. The position of sleepers should avoid welding seams and detection tubes. After the storage tank is hung on the transport truck and placed stably, it is necessary to confirm again whether the storage tank detection pressure gauge is -0.035Mpa. The storage tank should be fixed with cotton and hemp rope straps. The place where the straps contact the storage tank must be lined with rubber to prevent the FRP layer on the surface of the storage tank from being pinched. It is strictly forbidden to use metal ropes to fix the storage tank. After the storage tank is fixed, it must be covered with rainproof cloth or oil cloth.

Note that the storage tank must be steadily transported to avoid rapid advance, emergency stop or driving on bumpy roads.

Last article:

Next article:

Send Your Inquiry

We not only provide a good product, but also provide high quality service. If you are interested in our products,

you can contact us in the following ways.

you can contact us in the following ways.