Product Category

Welding process advantages of tank making

Date: Nov 13, 2019

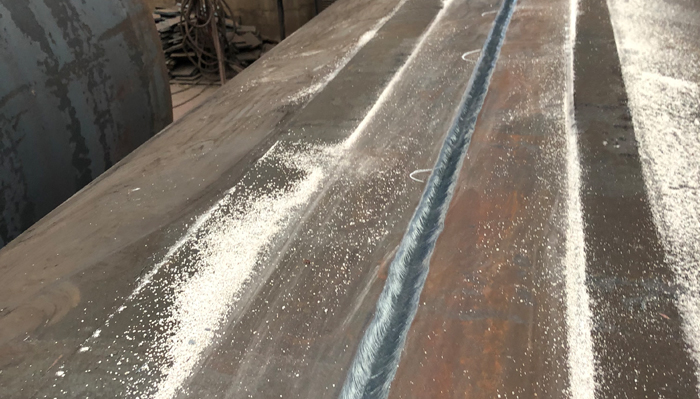

How to use steel plate to make a tank with good air tightness? Today we will explain the welding process of the tank during the production process. The welding process used by Jianshen company oil tanks, LPG tanks, LNG tanks and cryogenic storage tanks in the production and production is the submerged arc automatic welding welding process. The advantages of the submerged arc welding process are as follows:

1. High productivity. This is mainly because submerged arc welding leads the welding current to the welding wire through the contact nozzle. Compared with the electrode arc welding, the conductive wire has a short length, and the surface is not coated with the coating, and there is no limitation of the thermal decomposition of the coating component. Therefore, it is allowed to use a much larger current than the electrode arc welding, so that the arc power, the penetration depth and the melting speed of the welding wire of the submerged arc welding are correspondingly large. Under certain conditions, it is possible to achieve one-time penetration and double-sided forming of 10~20mm steel plates. In addition, due to the heat insulating effect of the flux and the slag, the arc is substantially free of heat radiation, and the metal splash is small. Although the heat loss for melting the flux is large, the total thermal efficiency is still greatly increased.

2. The weld quality is good. This is firstly because the arc and the molten pool are under the protection of the flux and the slag during the submerged arc welding, and the protection effect is better than the electrode arc welding. Secondly, the presence of flux also slows the solidification rate of the molten pool metal, and there is more time between the liquid metal and the molten flux for metallurgical reaction, which reduces the possibility of defects such as pores and cracks in the weld. In addition, during submerged arc welding, the welding parameters can be stabilized by automatic adjustment, the technical level of the welder is not high, the weld composition is stable, the surface is beautifully formed, and the mechanical properties are good.(The storage tanks produced by Jianshen Company have the characteristics of beautiful appearance and good air tightness)

3. The welding cost is low. This is firstly because the welding current used in submerged arc welding is large, so that the weldment can obtain a large penetration depth. Therefore, the weldment can be opened without a bevel or a small groove when submerged arc welding, thereby saving the processing of the groove. Consumed weld metal and machining man-hours also reduce the amount of wire filler in the weld. Moreover, since the metal splashes during welding are extremely small and there is no loss of the electrode tip, the filler metal is also saved. In addition, the heat of the submerged arc welding is concentrated and the thermal efficiency is high, so the electric energy consumed per unit length of the weld is also greatly reduced.

4. Good working conditions. Since the submerged arc welding realizes the mechanization of the welding process, the operation is relatively simple, and the operator only monitors the flux during the welding process, thereby greatly reducing the labor intensity of the welder. In addition, the arc is burned under the flux layer during submerged arc welding, without the harmful effects of arcing, and emits less smoke and harmful gases.

1. High productivity. This is mainly because submerged arc welding leads the welding current to the welding wire through the contact nozzle. Compared with the electrode arc welding, the conductive wire has a short length, and the surface is not coated with the coating, and there is no limitation of the thermal decomposition of the coating component. Therefore, it is allowed to use a much larger current than the electrode arc welding, so that the arc power, the penetration depth and the melting speed of the welding wire of the submerged arc welding are correspondingly large. Under certain conditions, it is possible to achieve one-time penetration and double-sided forming of 10~20mm steel plates. In addition, due to the heat insulating effect of the flux and the slag, the arc is substantially free of heat radiation, and the metal splash is small. Although the heat loss for melting the flux is large, the total thermal efficiency is still greatly increased.

2. The weld quality is good. This is firstly because the arc and the molten pool are under the protection of the flux and the slag during the submerged arc welding, and the protection effect is better than the electrode arc welding. Secondly, the presence of flux also slows the solidification rate of the molten pool metal, and there is more time between the liquid metal and the molten flux for metallurgical reaction, which reduces the possibility of defects such as pores and cracks in the weld. In addition, during submerged arc welding, the welding parameters can be stabilized by automatic adjustment, the technical level of the welder is not high, the weld composition is stable, the surface is beautifully formed, and the mechanical properties are good.(The storage tanks produced by Jianshen Company have the characteristics of beautiful appearance and good air tightness)

3. The welding cost is low. This is firstly because the welding current used in submerged arc welding is large, so that the weldment can obtain a large penetration depth. Therefore, the weldment can be opened without a bevel or a small groove when submerged arc welding, thereby saving the processing of the groove. Consumed weld metal and machining man-hours also reduce the amount of wire filler in the weld. Moreover, since the metal splashes during welding are extremely small and there is no loss of the electrode tip, the filler metal is also saved. In addition, the heat of the submerged arc welding is concentrated and the thermal efficiency is high, so the electric energy consumed per unit length of the weld is also greatly reduced.

4. Good working conditions. Since the submerged arc welding realizes the mechanization of the welding process, the operation is relatively simple, and the operator only monitors the flux during the welding process, thereby greatly reducing the labor intensity of the welder. In addition, the arc is burned under the flux layer during submerged arc welding, without the harmful effects of arcing, and emits less smoke and harmful gases.

Last article:

Next article:

Send Your Inquiry

We not only provide a good product, but also provide high quality service. If you are interested in our products,

you can contact us in the following ways.

you can contact us in the following ways.