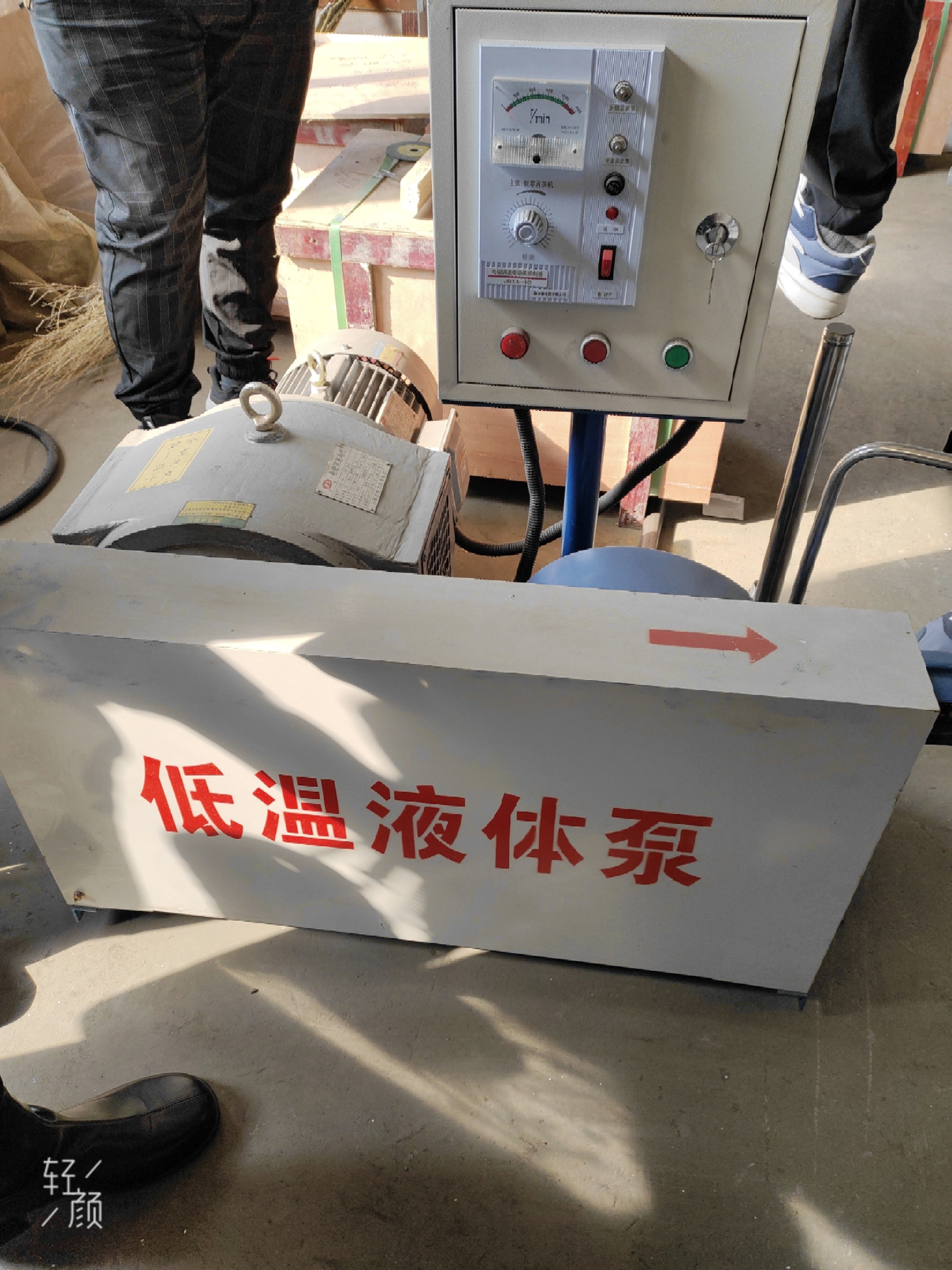

excellent quality cyogenic liquid pump in China market

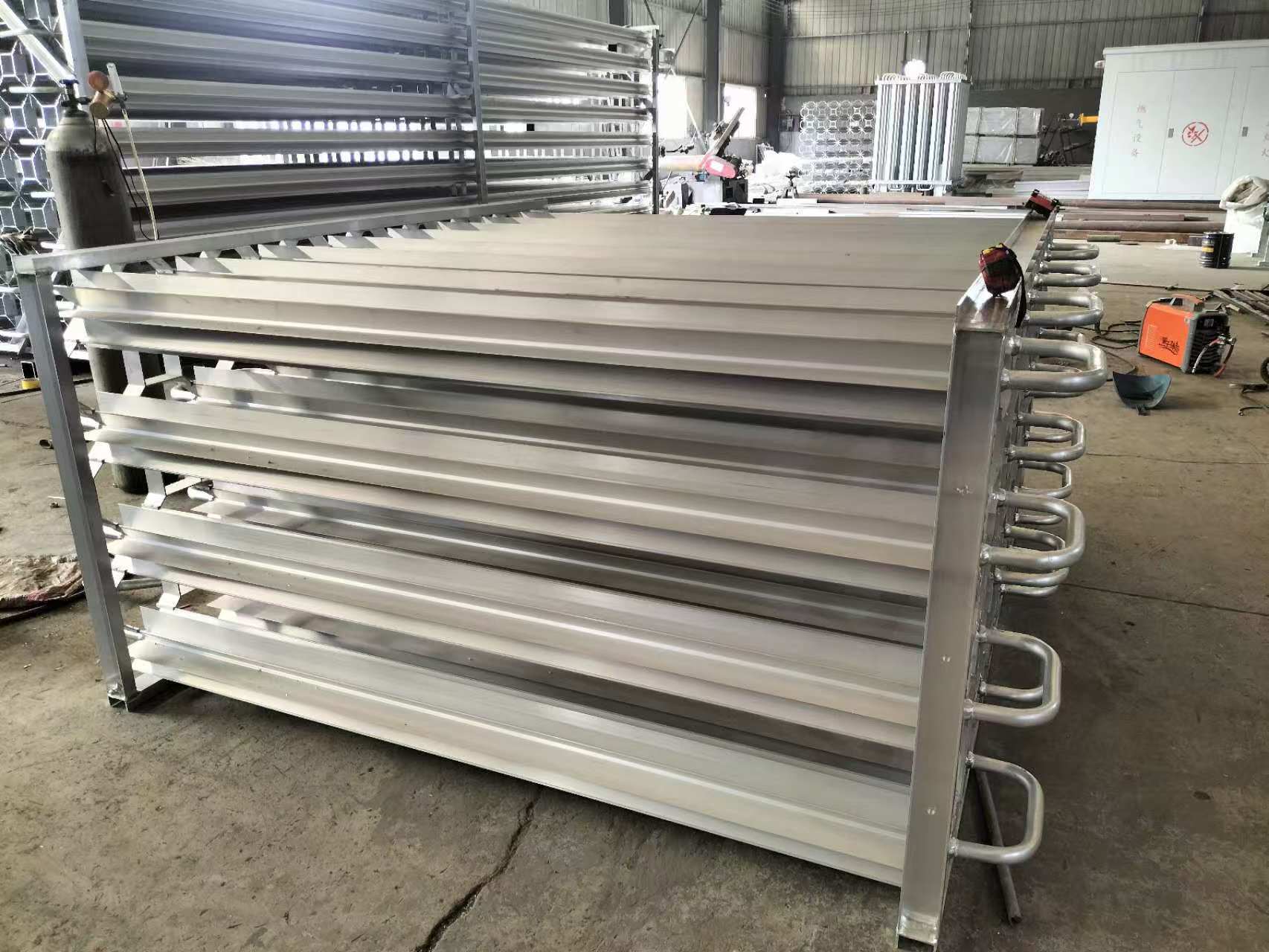

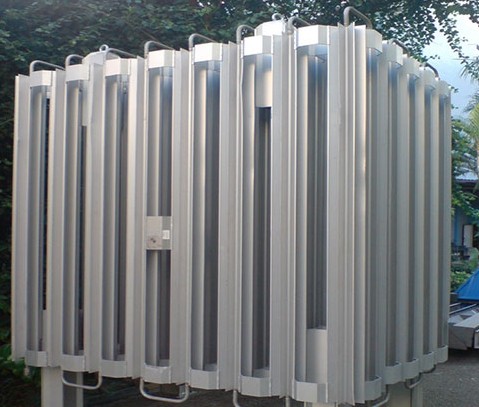

Cryogenic liquid pump is used to transport cryogenic liquid, and improve its pressure machinery. According to the principle of action, cryogenic pump can be divided into blade type and reciprocating two categories. Blade type includes centrifugal type, mixed flow type and axial flow type. Reciprocating plunger type and piston type.

Centrifugal pump is the most common type of vane type. The centrifugal type can be divided into single stage and multiple stage. The plunger pump is the most commonly used type of reciprocating, there are single column and multiple column. [2]

Centrifugal cryogenic pump is used for low and medium pressure transmission. Column cryogenic pumps are used for systems with high pressure and low flow.

Design considerations

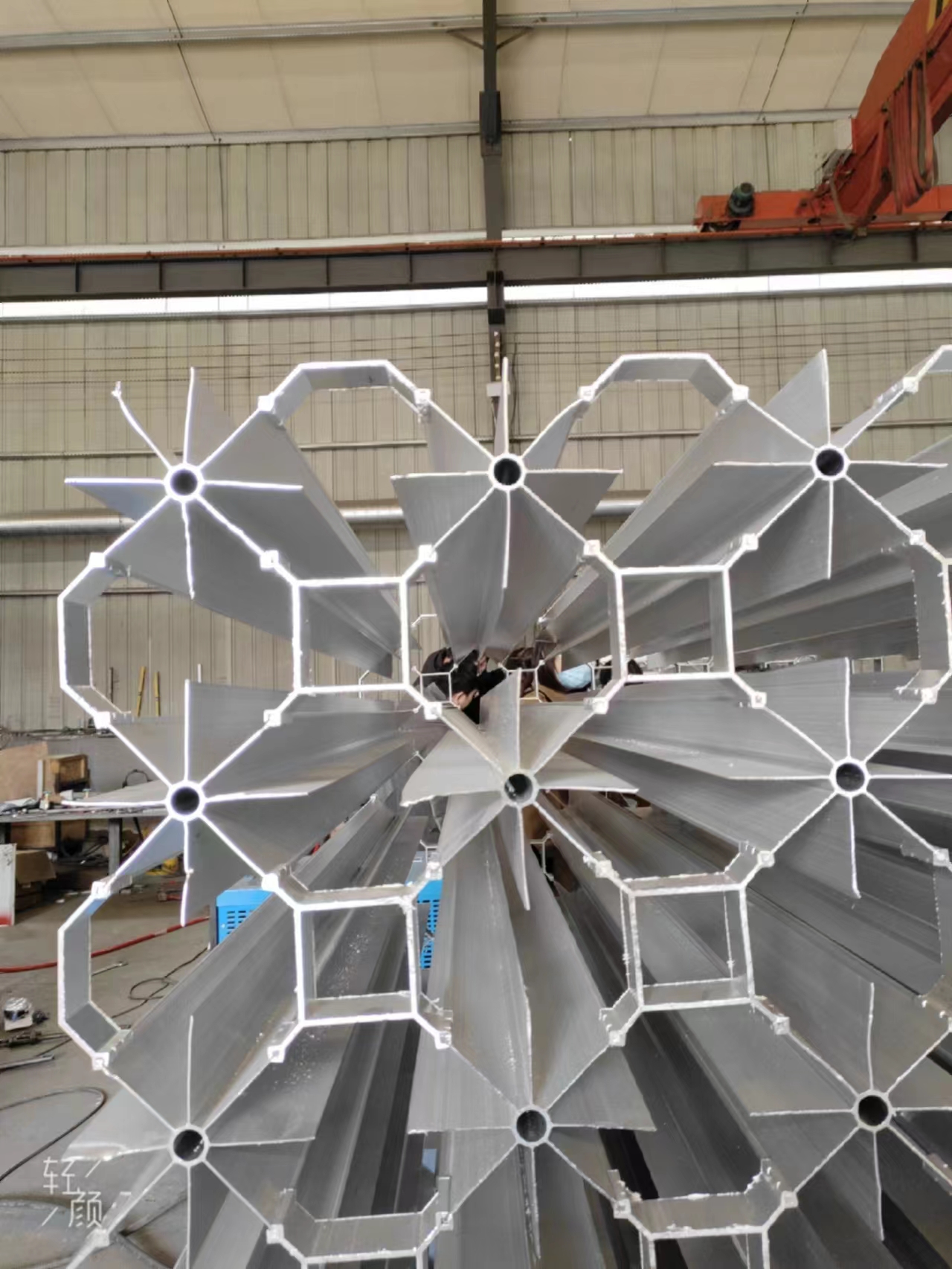

(1) The connecting parts between the normal temperature zone and the low temperature zone should be made of materials with low thermal conductivity to reduce thermal conductivity loss;

(2) as far as possible to reduce the heat capacity of parts working in the low temperature area, in order to reduce the loss of liquid vaporization, shorten the starting time;

(3) As far as possible, materials with similar coefficient of linear expansion are selected to make parts that work in low temperature areas and have relative motion; The linear expansion coefficient of the enveloped parts must be less than or equal to the linear expansion coefficient of the enveloped parts to prevent the phenomenon of sticking during cold shrinkage;

(4) For important parts working at low temperature, especially for those moving parts with very strict coupling requirements (such as the moving ring and static ring of shaft seal, plunger pump plunger and cylinder liner, etc.) before the final finishing, must be cold treatment. Cold treatment temperature should generally be lower than or equal to the working temperature, treatment time is 1 ~ 4 hours;