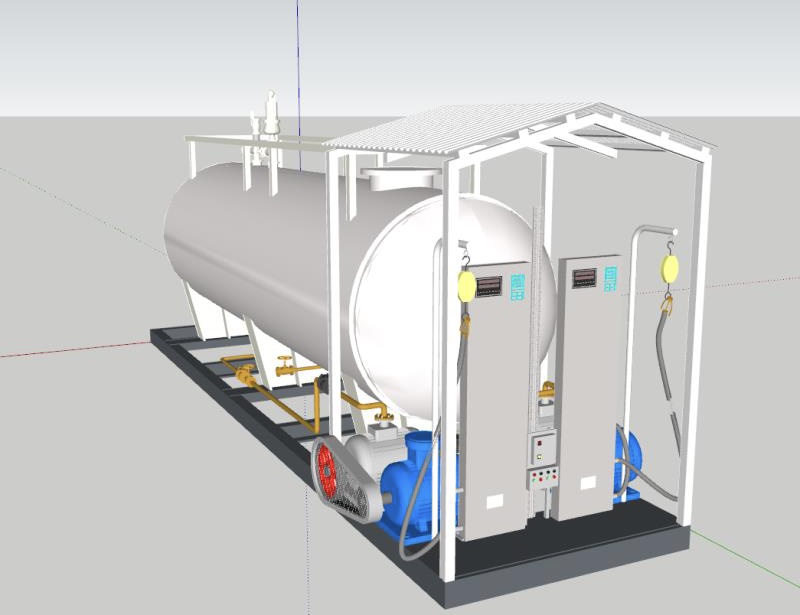

lpg filling station

The pressure should be the design pressure of the storage tank and pipe system respectively. Before the transfer station is filled with LPG, the system must be deaerated with nitrogen or vacuum to remove the air in the system.

The pressure should be the design pressure of the storage tank and pipe system respectively. Before the transfer station is filled with LPG, the system must be deaerated with nitrogen or vacuum to remove the air in the system. An installation check must be made before applying power to the power cable, and incorrect connections are strictly prohibited. Operators must be trained on equipment conditions and use prior to starting work. Operators must master the structure, principles and operating procedures of all equipment of the skid transfer station. and specializes in the structure, principle and working key points of gas dispensers, pumps, valves, etc. The worker’s clothing must meet the following requirements: No sparks. Each section of the loading station must be shaded. The spray system should be connected to a reliable water source to allow timely spraying and cooling of the tank.