Operating temperature of CO2 tank

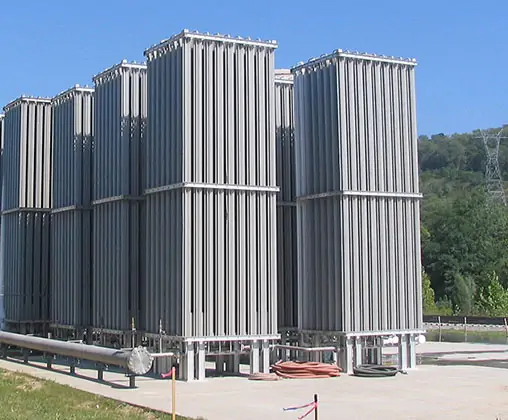

At low temperatures, CO2 has a low gas pressure. Tanks must be designed to withstand the pressure changes at low temperatures while avoiding abrupt changes between liquid and gas. As the temperature rises, the gas pressure of CO2 increases, which creates a greater pressure burden on the tank. Tank designs for high temperatures require additional pressure vessel safety design considerations, including pressure control valves and safety valves.

At low temperatures, CO2 has a low gas pressure. Tanks must be designed to withstand the pressure changes at low temperatures while avoiding abrupt changes between liquid and gas. As the temperature rises, the gas pressure of CO2 increases, which creates a greater pressure burden on the tank. Tank designs for high temperatures require additional pressure vessel safety design considerations, including pressure control valves and safety valves.

States of CO2

Low temperatures (below -56.6°C):

Liquid: At low temperatures, CO2 is usually present as a liquid. The higher density of liquid CO2 facilitates efficient extraction, such as by siphon systems.

Solid: If the temperature drops further, CO2 turns to a solid state (dry ice). Tank designs must accommodate this extreme condition, using materials that are cryogenically resistant.

Normal temperatures (0°C to 25°C):

Mixed liquid and gas: At normal temperatures, the state of CO2 depends on the pressure in the tank. If the pressure is high, CO2 may be present as a liquid; if the pressure is low, it may be present as a gas. This requires tank designs that can handle a mixture of gaseous and liquid CO2.

High temperature (above 25°C):

Gaseous state: At high temperatures, the vaporization pressure of CO2 increases and liquid CO2 may turn into gas. Storage tanks need to be able to withstand higher gas pressures and may require cooling systems to maintain the liquid state of CO2.