Oxygen gas supply system flow chart

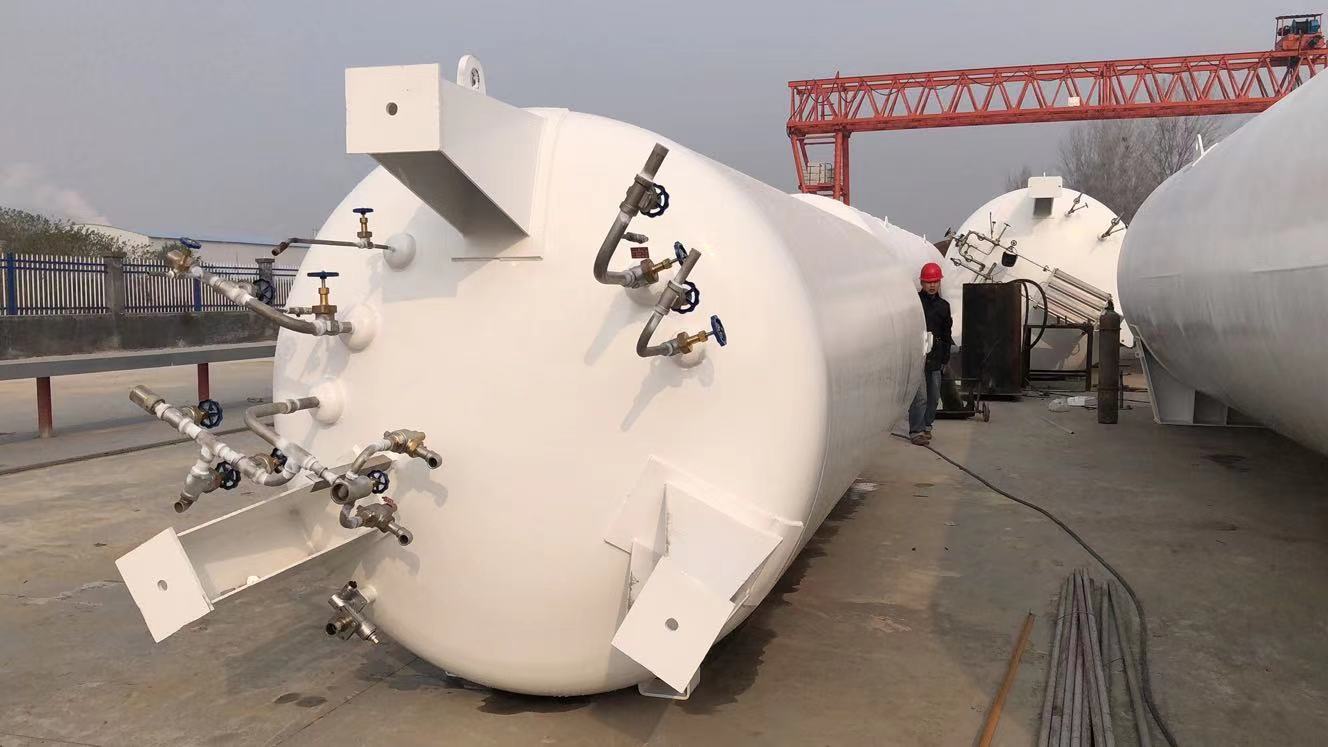

VIETNAM 3000 LITRES LOX TANK FLOW CHART 202205

In the development of modern industry, various cryogenic liquid storage tanks are used more and more frequently, mainly natural gas storage tanks, liquid nitrogen storage tanks, liquid oxygen storage tanks, liquid carbon dioxide storage tanks, and liquid argon storage tanks. Due to the slow degassing of the container material and the leakage rate of the vacuum interlayer seal, the insulation performance of the storage tank will decrease due to the lack of vacuum in the interlayer after a certain period of use. Gasification will lead to an increase in the pressure of the inner tank, followed by frequent deflation through the safety valve, and the stored liquid will also decrease rapidly when not in use, causing unnecessary economic losses. Once the thermal insulation performance of the storage tank is poor, the exhaust gas of the safety valve will frequently increase geometrically. Therefore, when the vacuum of the storage tank is missing, a professional vacuum pump set must be used to supplement the vacuum degree of the interlayer of the storage tank. Once the vacuum degree is restored to the factory value, the thermal insulation performance of the storage tank can be significantly improved.