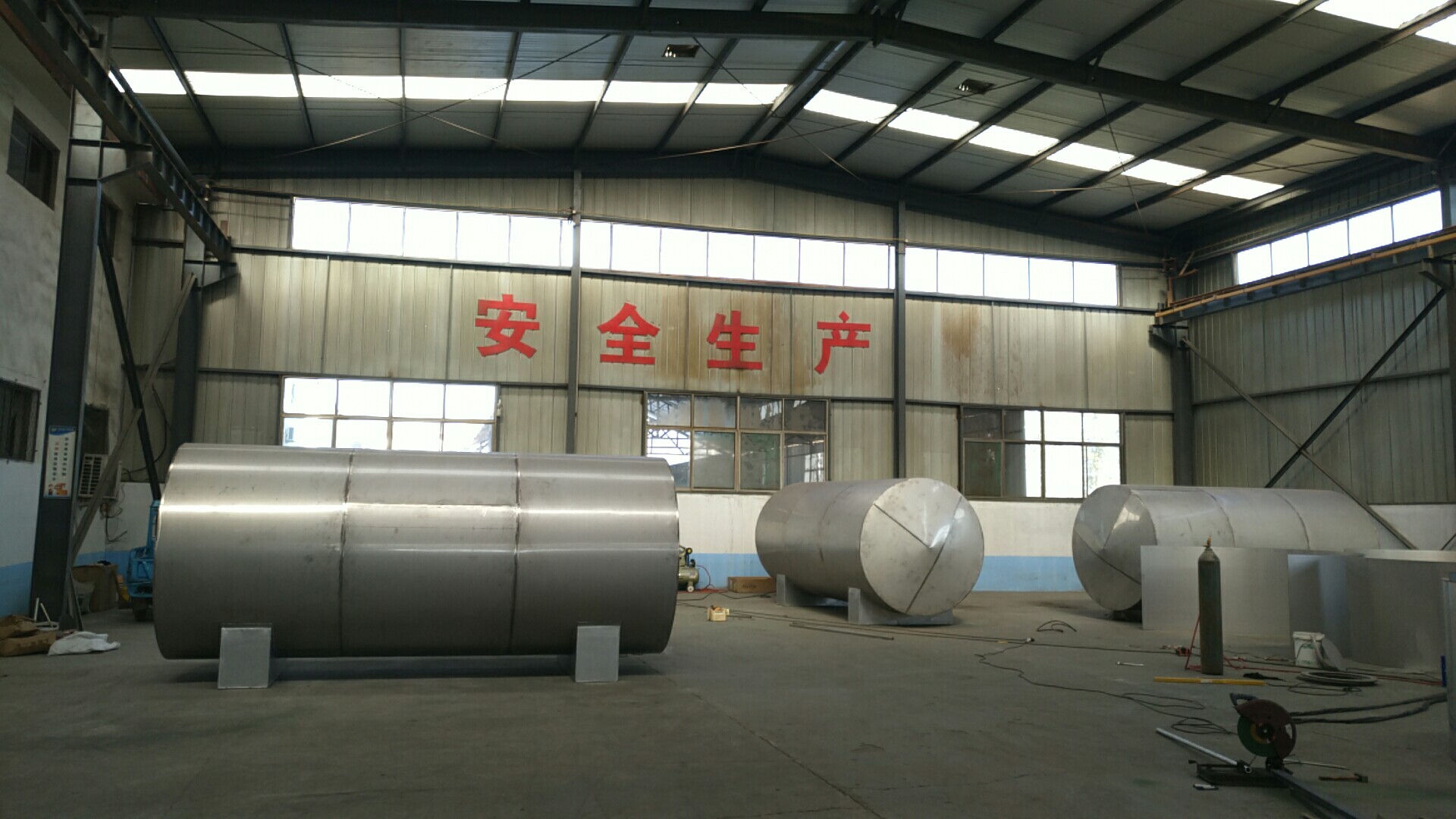

Reasons for fast assembly of aboveground oil tanks

Segmented assembly method; Advanced welding technology; Floating Plate Inner Operation Platform.

Segmented assembly method: the advantage of this method is that the construction preparation workload is less, the assembly speed is fast, the assembly stress is small, and the assembly accuracy is easy to grasp. In addition, this method does not require a large lifting machinery, and at the same time, the assembly platform can be omitted or only a simple platform.

Advanced welding technology: Submerged arc welding, TIG welding and other advanced welding technologies are used to weld and assemble the plates to form the main structure of the tank. These techniques improve the welding efficiency and thus speed up the assembly.

Floating Plate Inner Operation Platform: Using floating plate as inner operation platform, after assembling one circle of wall plate, fill water into the tank, so that the floating plate rises, and then assembles the next circle of wall plate until all the groups are finished. This method utilizes the buoyancy of water and the characteristics of the pontoon structure to provide convenient tank assembly.