Safety control measures for the use of liquid oxygen, liquid nitrogen, liquid argon tank

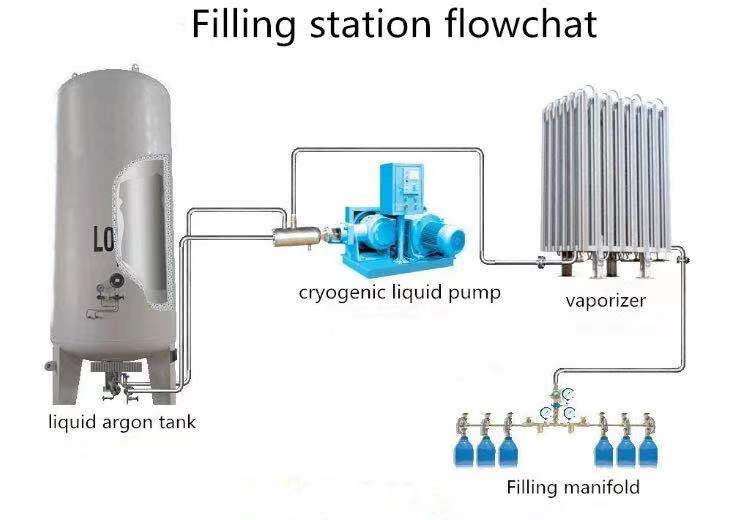

Liquid oxygen, liquid nitrogen, liquid argon and other low-temperature liquid gasifiers are widely used in liquid gasification stations, direct gas supply or bottle filling. In order to ensure the safe operation of the gasifier, safety control points should be set, and pay attention to the following matters.

1) Set the low-temperature control interlock point of the cryogenic liquid out of the gasifier. Control the gas outlet temperature from 5 to 30℃. When the outlet temperature is lower than 0C, the liquid pump will be automatically cut off and the liquid will be suspended from entering the gasifier. The gasifier without liquid pump will issue an audible and visual alarm.

2) Set the gasifier water temperature control interlock point. Control the water temperature at 40~60℃. When the water temperature is lower than 30C, the liquid pump will be cut off automatically to stop the liquid from entering the gasifier;

3) Set the gasification gas outlet pressure control interlock point to control the pressure at the set value. When the outlet gas pressure is higher than the set value, an audible and visual alarm will be issued; if the pressure continues to rise, the liquid pump will be automatically cut off and the liquid will be stopped from entering the gasifier;

4) In the liquid pump with a shut-off valve at both ends of the part should be installed with a safety valve and emptying valve to ensure the safety of misoperation

5) gasifier supporting pressure gauge, safety valve should be regularly calibrated;

4) in the liquid pump with a shut-off valve at both ends of the part should be installed with a safety valve and venting valve to ensure the safety of the misoperation.

5) the pressure gauge and safety valve supporting the gasifier should be regularly calibrated

6) the upper and lower limits of the storage tank level alarm device & Gasifier heated with a water bath must be filled with water from the tank before use, and heated to 40 ~ 60 ℃ before supplying the liquid. Before stopping the gasifier, then the liquid delivery valve should be cut off first, and then cut off the heating power after the heat. Gasification process should often pay attention to the water level, timely replenishment of diao amount;

7) work process due to changes in the flow rate, will affect the temperature after gasification, so the water temperature should be adjusted in a timely manner;

8) If it happens that the water temperature drops below 30° C, the electric heater should be checked to see if it is damaged. If necessary, the output flow rate should be reduced to ensure the temperature after gasification. The pipeline from gasifier to filling should stop filling when ice or frost is found.