Safety Regulations for Oxygen Filling

I、Operation points

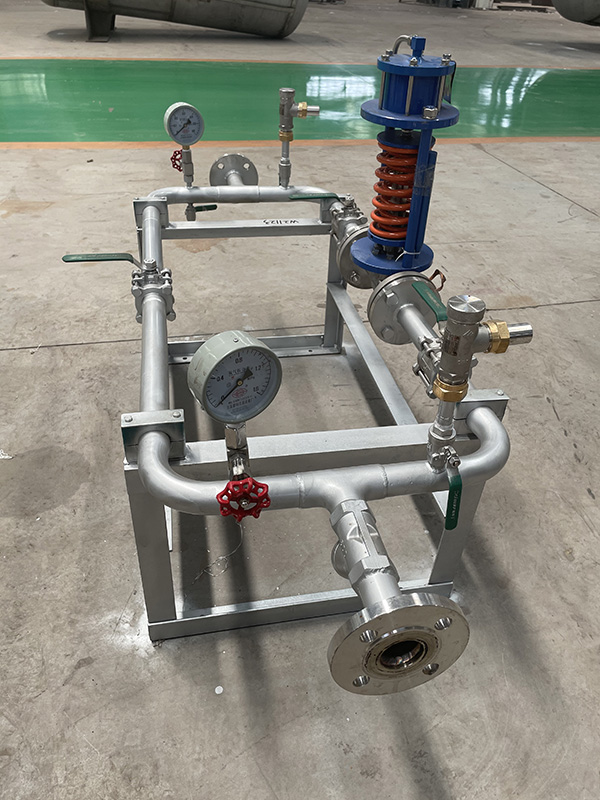

1.1 Before filling, carefully check the filling equipment, pipelines, valves, instruments, and tooling fixtures, and work only after they are safe, sensitive and reliable.

1.2 The gas cylinder must be inspected and approved for filling. After pushing the gas cylinder to the filling station, connect the filling metal hose to the cylinder valve firmly and reliably, then open each cylinder valve, observe and eliminate air leakage, and prepare for inflation.

1.3 When the cryogenic liquid pump and vaporizer work normally and supply air, slowly open the main intake valve on the filling row, and notify the liquid pump operator.

1.4 From the start of filling, the change in filling pressure should be observed at all times. When the pressure rises to 1/3 of the filling pressure, the temperature of the cylinder should be checked. If you find that the cylinder is not filling (no warming of the cylinder wall by hand) or leaking during the inspection, you should deal with it promptly. If no gas is fed, check if the valve is open; if gas is leaking, the filling of the leaking cylinder should be terminated, but when the pressure exceeds a certain amount or when it is inconvenient to handle, the filling of the cylinder cannot be terminated, and the group of cylinders should be removed from the filling row to be handled after the filling is finished.

1.5 Close the main valve of this group of inflatable sinks and slowly open the main valve of another group of inflatable sinks to start another group of gas cylinder filling. Then, close the valve of each cylinder that has been inflated and slowly open the bleeder valve on the manifold to exhaust the remaining gas in the pipeline, remove the cylinder from the filling row, put on the cap and send it to the designated area for inspection.

1.6 Operators must wear protective gear that meets the requirements, comply with the safety regulations for gas filling, keep good filling records and not leave their work station at will.