The structure of the Dewar flask

The Dewar flask is mainly composed of two layers of containers, an inner and outer container, with a vacuum layer between the two containers for thermal insulation.

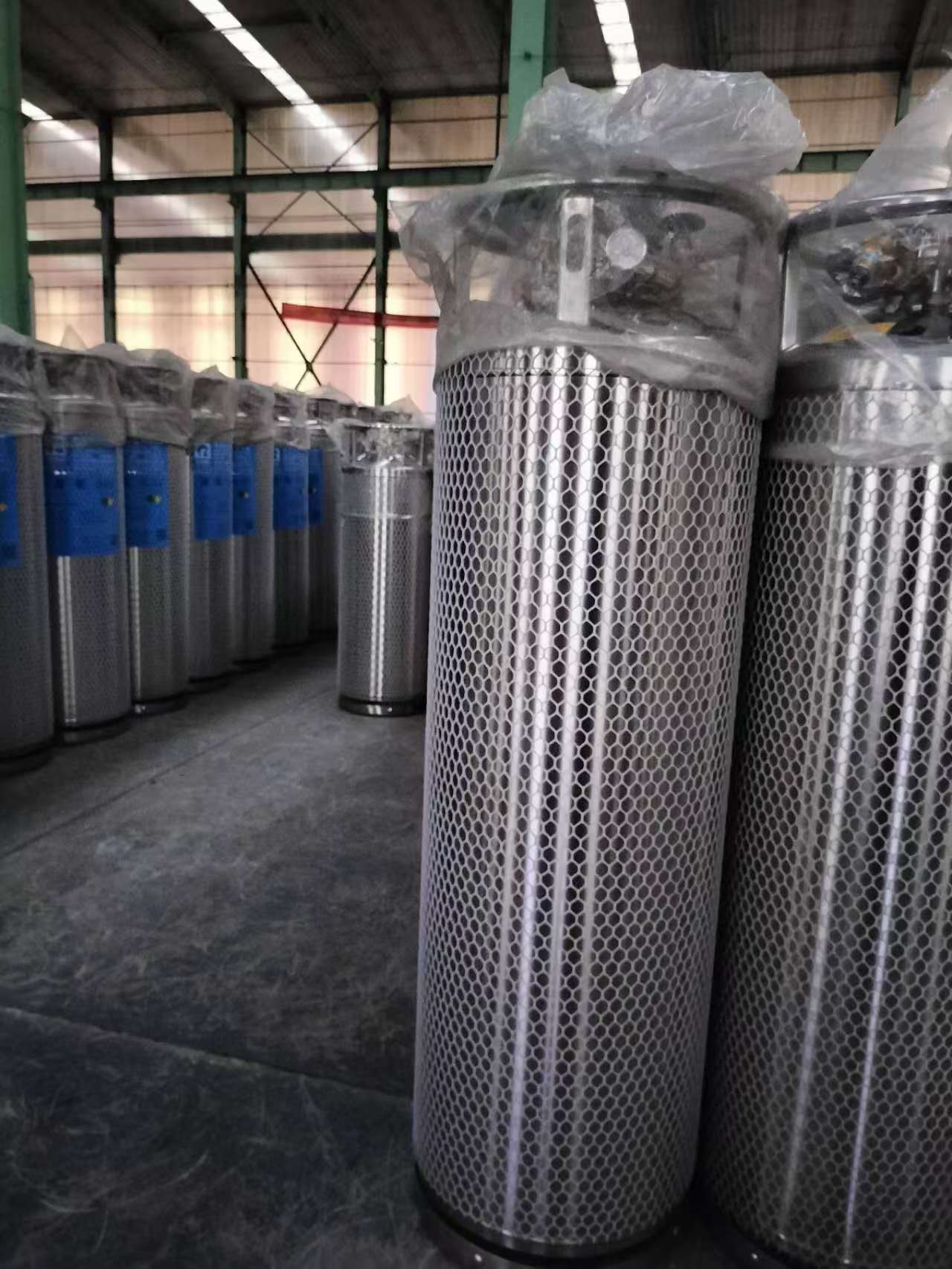

The Dewar flask is mainly composed of two layers of containers, an inner and outer container, with a vacuum layer between the two containers for thermal insulation. The inner container is usually made of stainless steel and is responsible for directly storing liquid oxygen or other cryogenic liquids. The outer container protects the inner container from the external environment and is also the boundary of the vacuum layer.

In addition to the vacuum layer, the inner and outer containers are filled with insulating materials such as fiberglass or foam plastics to further improve the thermal insulation effect. This structural design can minimize heat transfer and ensure that the liquid oxygen remains liquid in the inner container for a long time.

The Dewar flask is also equipped with valves and piping systems to control the flow and release of liquid oxygen. The valves are usually located on the top or side of the Dewar flask for easy user operation. The piping system transports the liquid oxygen from the inner container to external equipment or use points.