Working principle of LPG multistage pump

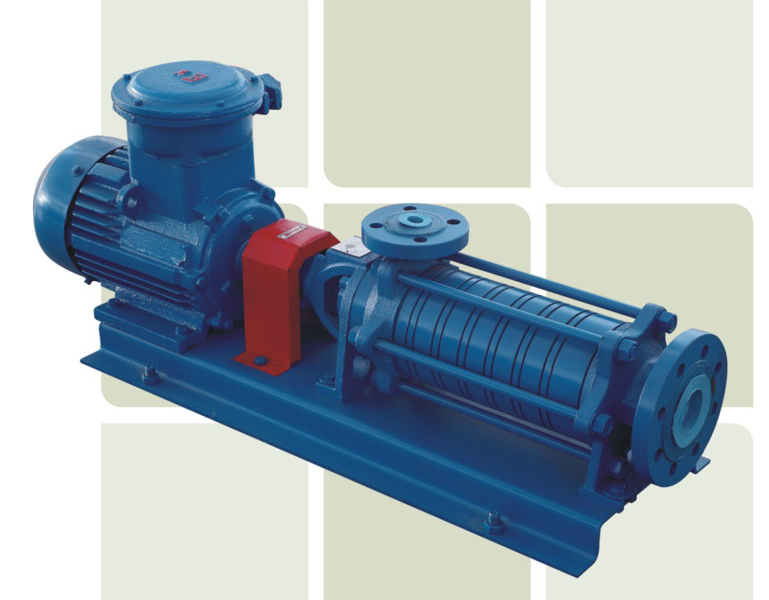

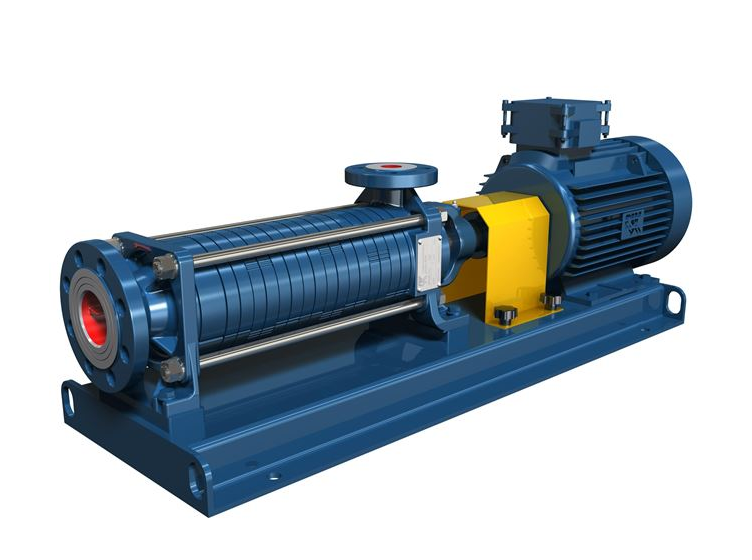

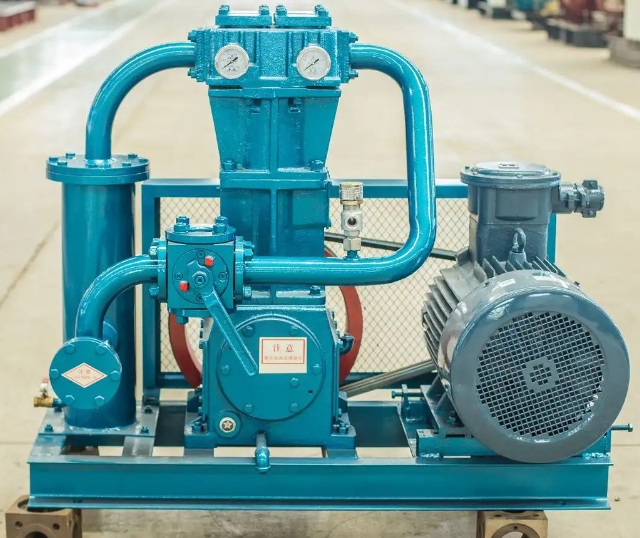

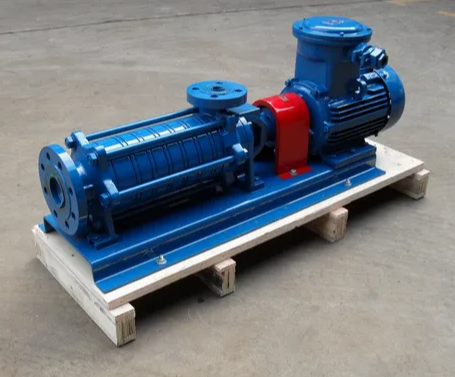

The working principle of the liquefied petroleum gas (LPG) multi-stage pump is based on the design of multiple impellers connected in series, aiming to achieve high-pressure and high-lift liquid transportation.

The working principle of the liquefied petroleum gas (LPG) multi-stage pump is based on the design of multiple impellers connected in series, aiming to achieve high-pressure and high-lift liquid transportation. The working process of this pump can be divided into several key steps. First, when the pump starts, liquid flows into the pump body through the water inlet and fills the pump chamber. At this time, a liquid-filled environment is formed inside the pump, ready for the next work.

Next, the electric motor drives the impeller inside the pump to rotate. When the impeller rotates, the liquid flows outward from the center of the impeller under the action of centrifugal force. The design of the impeller significantly increases the speed and kinetic energy of the liquid during rotation. After the liquid passes through the first impeller, it enters the next impeller, further increasing its pressure. The design of this multi-stage structure allows the liquid to gradually increase the pressure in each impeller, thereby achieving high head.

Finally, the liquid that has passed through all impellers is discharged from the outlet of the pump at high pressure and enters the delivery pipeline or storage system. During the entire process, the pump is able to maintain stable flow and pressure, ensuring continuous circulation of liquid in the system.